Eighteen years after Richard Allen first conceived the idea of using synthetic turf to create low maintenance, high durability edging for bunker walls, industry pioneer EcoBunker has announced the latest in its long line of innovations in the sector – pre-cut synthetic tiles.

“EcoBunker Advanced was the last big step forward we took in bunker edge technology,” said Allen, CEO of EcoBunker and inventor of synthetic bunker edging. “That enabled us to build bigger, stronger walls with fewer synthetic tiles, so the impact on the business and our bunkers was very dramatic. While our latest innovation, pre-cut tiles, might not be as obviously impactful, the results we are seeing from early adopters are quite remarkable.”

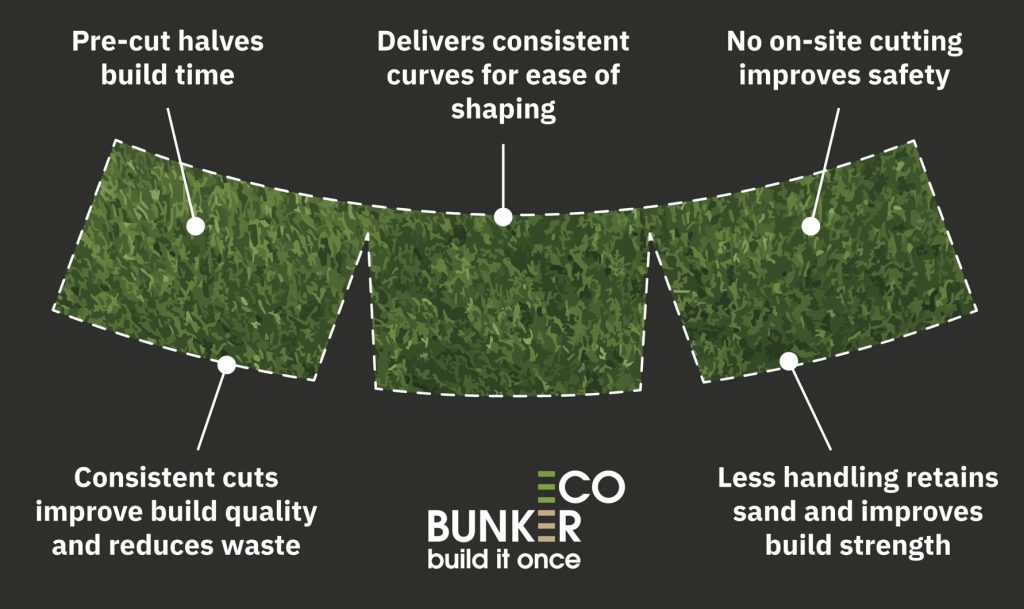

The process of installing traditional EcoBunker Advanced walls and edging involves the individual cutting of each tile to provide the flexibility required to shape the bunker wall. With the new pre-cut tiles, build time on each project is dramatically reduced, while quality, consistency and safety are all increasing.

“Pre-cut might not sound much, but an average bunker uses 750 synthetic tiles so that’s a lot of time saved! But it’s not just the cutting time,” continued Allen. “Greenkeeping staff have to wet pallets if they become dry, handle tiles with care when they turn them over, and they have to use a Stanley knife to hand-cut each tile. When you also account for all that time unstacking and re-stacking, we have been able to reduce the average bunker build by half on several projects. And when we pre-cut, each tile has exactly the same cut. This all adds up to a very high level of quality, consistency and durability.”

One club that has already used pre-cut tiles in the third phase of their work with EcoBunker is Lundin Links. Having previously used traditional EcoBunker Advanced technology, course manager, Gavin Neill, noticed an immediate and significant impact.

“For the first two phases of our bunker restoration project we used EcoBunker Advanced and the results have been fantastic,” Neill said. “The new bunkers look great and have significantly cut down on maintenance time. For the most recent phase we used the new EcoBunker pre-cut tiles and couldn’t believe the time we saved on installation. We are now able to build bunkers in half the time. Eliminating all on-site cutting also means that not only is it quicker, but it’s safer and reduces the number of waste tiles.”

While the introduction of pre-cut offers immediate advantages for clubs who are looking to build new bunkers themselves, the benefits of the new system are also available for clubs who want to commission a bunker project.

Andrew Greenslade, Managing Director at AMG Golf Course Renovation, said: “As a contractor who regularly installs EcoBunker products, having the option to buy pre-cut Advanced Tiles is a major advantage for us. It removes the need to spend time on site cutting tiles, which immediately reduces labour hours, accommodation and travel costs, and allows us to offer more competitive and transparent quotes to clubs. Pre-cut tiles also mean we can start construction as soon as we arrive, rather than losing one or two days preparing materials. This keeps the programme tight and helps us deliver projects more efficiently.”

“We’ve introduced several advancements to the bunker sector, but this has actually been one of the most difficult to perfect.” concluded Richard. “Now we have the tooling and methodology to create consistent cuts every time, this will revolutionise the way in which greenkeeping teams approach a bunker project. All the advantages of EcoBunker technology remain – significantly lower maintenance, increased longevity, sustainability and zero sand contamination – and all of that is now accessible in half the time.”